Catalogue

Industrial, Storage and Plastic Tanks

For more than 50 years, ACO Container Systems is recognized as one of the leading manufacturer of quality polyethylene, plastic storage tanks, and rotationally molded products.

Closed Top Vertical Storage Tanks

At ACO, we are committed to providing superior vertical storage tanks that cater to many industries across Canada and the USA. Our design expertise extends to creating seamless, one-piece, closed-top storage tanks.

Open Top Storage Tanks

Looking for a top-quality open tank that’s perfect for your liquid mixes? Our seamless, one-piece tanks are manufactured out of high-grade HDPE or XLPE resin and are FDA compliant and NSF 61 listed.

Tote Barrels

Mount a metering pump on these tanks to improve your feed and metering applications. They offer excellent chemical resistance and withstand low temperatures with their seamless, durable UV-stabilized HDPE resin design.

Double Wall Storage Tanks

Looking for a high-quality storage tank that’s perfect for chemical storage? Look no further than our seamless, one-piece Double Wall Storage Tanks. Manufactured out of durable HDPE or XHDPE/XLPE resin, these tanks can be FDA compliant.

Cone Bottom Tanks

Sloped Bottom Tanks

Introducing an exclusive innovation from ACO Container Systems our cutting-edge tank design features a Sloped Bottom towards the outlet, ensuring 100% complete drainage between batches.

Horizontal Tanks

Round Tanks

Utility Tanks

Introducing our Utility Tanks the perfect blend of reliability and smart design.

Pallet Tanks

Pallet Tanks are the perfect solution for anyone looking for a versatile and reusable container. With an integrated pallet base mount, Pallet Tanks can be easily maneuvered with a forklift or pallet jack. They’re available in a metal frame.

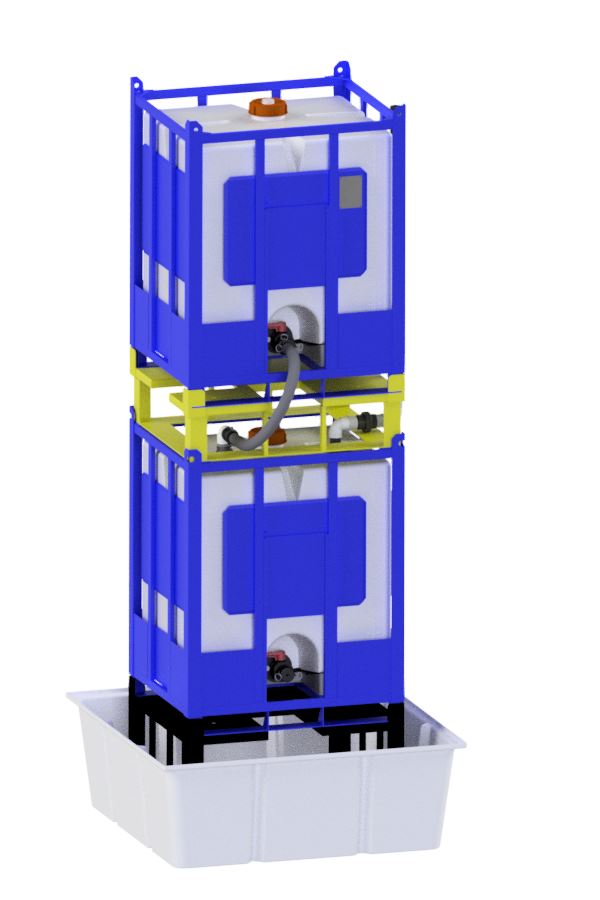

Mother Bin

Discover the ultimate solution for chemical transfer with ACO Mother Bin Systems. Engineered for efficiency, our mother bins are designed to streamline the transfer process from your chemical supplier’s IBCs to your feed system.

Feed Stations

Secondary Containment Basins

Material Handling Containers

Custom Tanks

Foaming and Heat trace

Ensure safe and effective warming of poly tanks to maintain the desired temperature of sensitive fluids with our advanced insulation and heat tracing solutions.

Fitting & Accessories

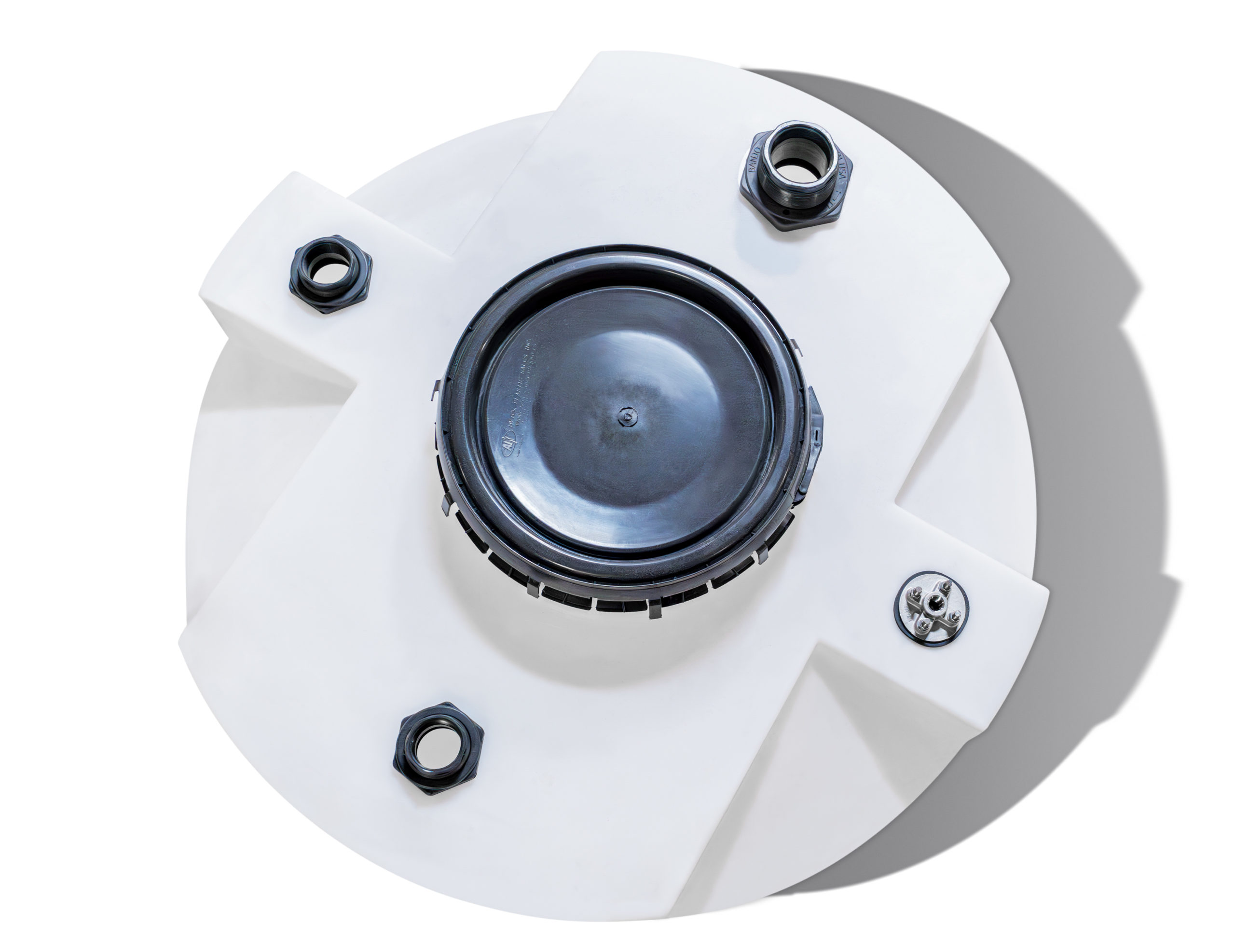

IBC Accessories

Discover our accessories specially designed for IBCs. Each part is designed to maximize the functionality of your containers. Some accessories are included by default with our IBCs, but all are also available individually to meet your specific needs.

FAQS

Frequently Asked Questions

ACO Container Systems, a division of Rotoplast Inc., is known as one of the leading manufacturers of high-quality, rotationally molded tanks and other rugged polyethylene products in North America. We have more than 50 years of experience in this business and are ISO 9001:2015 certified.

With our sister company, Rotoplast Inc., we can make custom plastic molded parts. Our team of professionals will assist you throughout the design and manufacturing processes. We’ll help you reach specifications that meet your requirements.

Contact us to discuss your custom project requirements. Our custom design team will be pleased to assist you.

GeT IN TOUCH

What will Be Next Step?

Review Your Inquiry

Our team will carefully review the information you've provided to understand your needs and requirements.

Follow-Up

We’ll reach out to discuss your project in detail and answer any questions you might have. Expect a call from us soon.

Receive a Proposal

Based on our discussion, we’ll prepare a tailored proposal that outlines solutions and next steps to move forward effectively.

Write us a few words about your project, and we’ll prepare a detailed proposal for you within 24 hours.